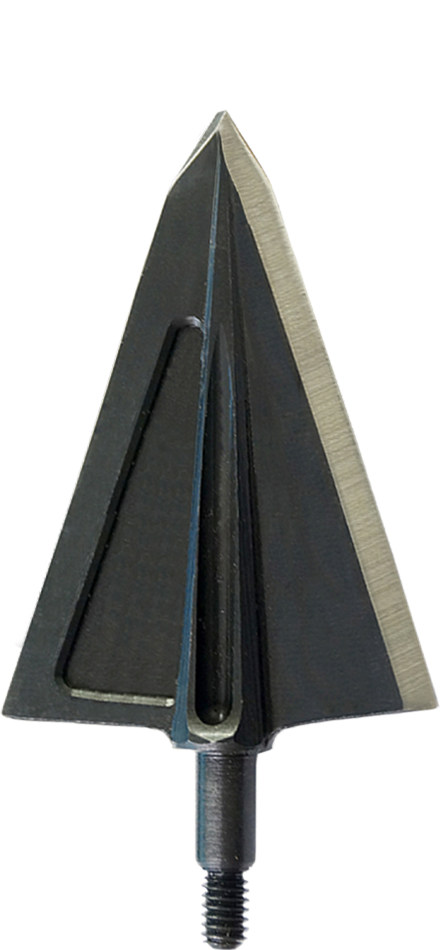

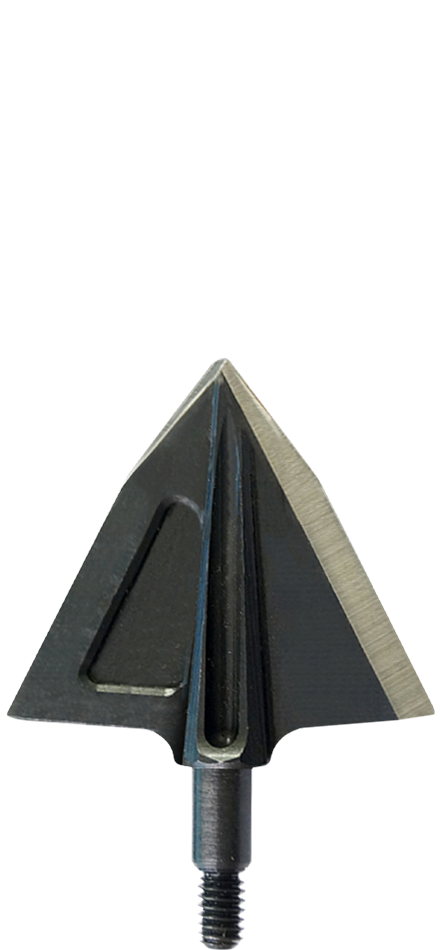

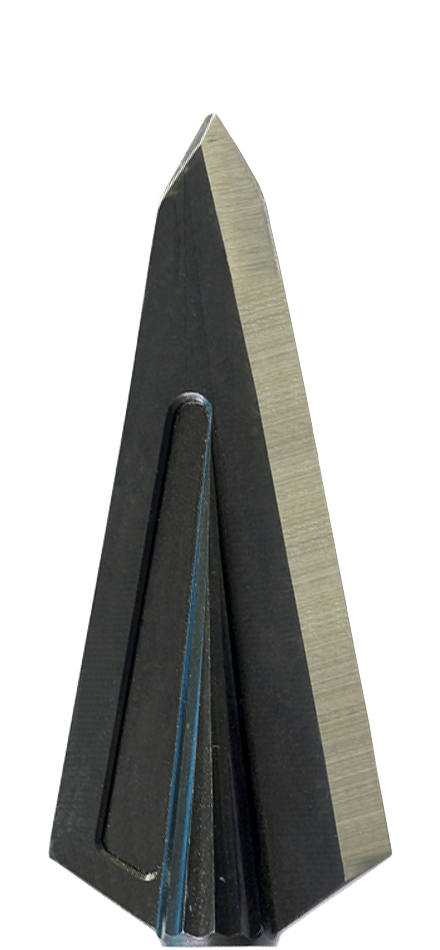

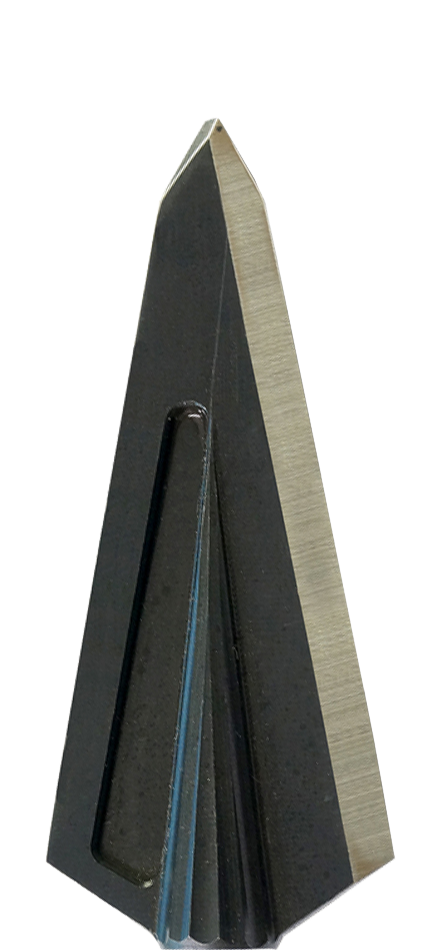

All Cutthroat Broadheads are made here in the USA. They are all machined from one piece of 100% steel for maximum strength. All broadheads have a cut-on-contact, tanto point, and they are all Teflon coated. The bevel is ground at 25° for maximum bone splitting torque while still maintaining structural integrity. Cuttroats are hardend to 55HRC, a nice balance between hardness and sharpen-ability.

Cutthroat Broadheads have taken this deadly broadhead design and produced it with the tools of today. It is machined out of one piece of solid steel. No welds or braze lines to fail. No crooked ferrules. No weak spots.

Cutthroat Broadheads are sold with a lifetime guarantee. If it bends or breaks it will be replaced!

Certain models are now available in S7 Tool Steel! Classified as a shock resistant steel, S7 offers exceptional impact toughness and strength to withstand chipping, bending or breaking. Impact resistance should be considered the most important characteristic of a broadhead steel. Hardened to 57-58HRC, you will have more than enough edge retention to efficiently cut from one end of the animal to the other. This steel is commonly used in dies, chisels, punches and concrete busters. If you are looking for the best possible material available to build a broadhead, in our opinion, this is it!

The Cutthroat 3-Blade Broadheads are built with a convexed profile in order to give the tip more material. The Cutthroat 3-blade tip is one of, if not the toughest 3-blade tip on the market. If you want an indestructible 3-blade broadhead, here it is.

SCREW-IN

Wide Cut

Wide Cut

or S7

or S7

or S7

or S7

GLUE-ON

3-BLADE